Live Chat

Click the button15000 BPH Carbonated Water Filling Machine / Production Line Commercial For Fruit Drink

The carbonated beverage filling line is mainly used for filling carbonated drinks such as cola, liquor, strong drink, foaming beverage and so on.

This is an automatic device, which integrates washing, filling and screwing. The cleaning head adopts the turnover device, and the filling system is gravity filling, which is more stable and reliable. The head adopts the advanced technology of Italy.

Products

-

Bag Filling Machine

-

Beverage Filling Line

-

Biscuit Making Machine

-

Biscuit Production Line

-

Bottle Blowing Machine

-

Carbonated Drink Production Line

-

Cosmetic Filling Machine

-

Drink Production Line

-

Drinking Water Filling Machine

-

Drinking Water Production Line

-

Edible Oil Production Line

-

Fruit Juice Processing Line

-

Juice Filling Machine

-

Plastic Injection Molding Machine

-

Snack Food Production Line

-

UHT Milk Processing Line

-

Water Treatment Systems

-

Vertical Packaging Machine

-

Other Packaging Machine

-

Pillow Type Packaging Machine

-

Pre-made Pouch Packing Machinery

-

Measuring Equipment

-

Cup Filling Machines

-

Conveyor Equipment

-

Auxiliary Equipment

Automatic RO Water Treatment Plant , Stainless Steel Water Treatment Equipment

Litchi / Pulp Juice Filling Machine High Capacity Semi- Automatic CE Certificate

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

3 In 1 Plastic Bottle Beverage Filling Machine , Automatic Soft Drink Filling Machine

Red Bull Energy Drink Production Line Automatic For Glass / PET Bottle

Fully Automatic Drinking Water Filling Machine 600-3000BPH For 5 Gallon PET Bottle

Bottled Mineral Drinking Water Production Machine / Filling Production Line

SUS304 PET Bottle Edible Oil Bottle Filling Machine For Non Viscous Liquid Filling

| Type: | Carbonated Soft Drink Filling Machine | Condition: | New |

|---|---|---|---|

| Driven Type: | Electric | Product Name: | Soft Drink Filling Machine |

| Capacity: | 8000-10000BPH 500ml | Degree Of Automation: | Full Auotmatic |

| PLC/ Transducer/ Touch Screen: | Siemens | Contactor/ Air Switch/supply: | Schneider |

15000 BPH Carbonated Water Filling Machine / Production Line Commercial For Pet Bottle

Product Description

The carbonated beverage filling line is mainly used for filling carbonated drinks such as cola, liquor, strong drink, foaming beverage and so on.

This is an automatic device, which integrates washing, filling and screwing. The cleaning head adopts the turnover device, and the filling system is gravity filling, which is more stable and reliable. The head adopts the advanced technology of Italy.

The machine adopts advanced SIEMENS PLC and touchscreen to guarantee the stable operation. The empty bottle is conveyed to the 3 machine 1 by air conveyer. The output bottle adopts the flat conveyor with frequency converter to ensure that the speed of the filling machine is adjustable.

Product Advantage

- The beverage filling machine adopts the advanced magnetic clutch screw cap, the torque can be adjusted, tighten the safety and reliability.

- The direct connection technology is adopted in the bottle with the feeding and the moving wheel. Remove the screw and the conveyor chain, which makes the bottle easy.

- When the output bottle spirals down, the transformation bottle shape does not need to adjust the height of the conveyor chain.

- Using the programmable controller as the control center, the pressure transmitter and electromagnetic measurement are adopted to maintain the equilibrium of the liquid surface, thus ensuring the stability of the liquid.

- The newly designed filling valve, return air and filling fluid are separated to ensure the cleaning of the filling material.

- Cylinder drive valve movement is accurate and reliable. High flux, high precision filling valve, filling fast and accurate. Equipped with CIP circuit and control program, the equipment is easy to clean.

- The specially designed stainless steel bottle washer is strong and durable, and has no contact with the thread of the bottle mouth to avoid secondary pollution.

- The bottle transmission adopts the bottleneck technology, the bottle shape transformation does not need to adjust the equipment level, just change the correlation curve board, the wheel and the nylon parts are enough.

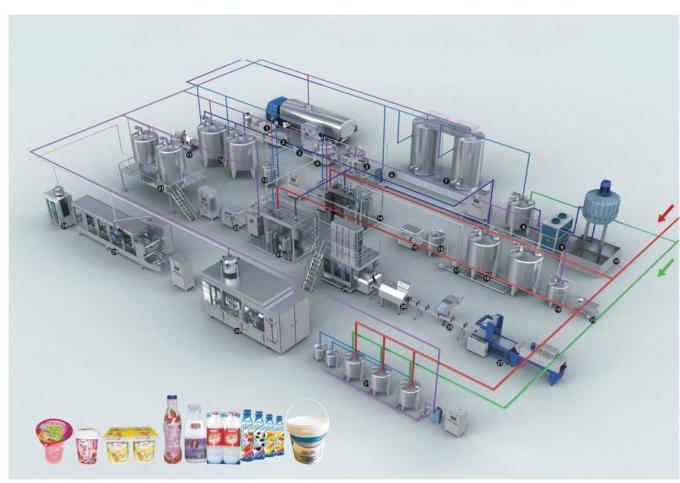

Flow Chart

We are able to supply whole production including :

Water treatment system

– Blow molding machine

– CSD preparation and mixing system

– Bottle unscrambler/Manual bottle loading system

– Air conveyor

– Rinsing-filling-capping 3-in-1 monoblock

– Bottle Warmer

– Labeling Machine

– Water Blow Drier,

– Lampinspection,

– Code ink jetter

– Shrink wrapper / carton packaging machine

– Palletizing system

– Conveying System

Product Sepcifications

| Rinsing Heads | 18 pieces |

| Filling Heads | 18 pieces |

| Capping Heads | 6 pieces |

| Processing Types | Isobaric Filling |

| Usage | Carbonated Drinks, Soft drinks, Beverage, CSD |

| Raw Material | Stainless Steel 304/316 |

| Control | Siemens PLC |

| Suitable Bottle diameter | 50-115mm |

| Suitable Bottle height | 160-320mm |

| Capacity | 5000 bph for 500ml |

| Product | whole carbonated drink filling machine,soft drinks bottling plant,soft drink production line/carbonated beverage filling machine |

| Model | MT24-24-8 | MT32-32-10 | MT40-40-12 | DCGF50-50-15 | DCGF60-60-15 |

| Rising heads | 24 | 32 | 40 | 50 | 60 |

| Filling heads | 24 | 32 | 40 | 50 | 60 |

| Capping heads | 8 | 10 | 12 | 15 | 15 |

| Capacity based on 500ml PET bottle | 7000BPH | 10000BPH | 15000BPH | 22000BPH | 24000BPH |

| Suitable bottle shape | PET bottles with different volume and shapes | ||||

| Suitable bottle diameter(mm) | Φ50-115 | ||||

| Suitable bottle height | 160-320mm | ||||

| Compressed air pressure | 0.3-0.7MPa | ||||

| Washing water pressure | >0.06MPa,≤0.2MPa | ||||

| Motor power (KW) | 4.5 | 6.0 | 7.5 | 9.5 | 11.2 |

| Dimensions(mm) | 3100*2200*2800 | 3850*3000*2850 | 4850*3800*2750 | 5750*3550*2750 | 6500*5500*2750 |

| Weight (KG) | 4800 | 6800 | 8650 | 10500 | 12800 |

Product Pictures

OutPut Product

Packaging & delivery

Our Service

- Be responsible for the installation and commissioning of the equipment by experienced engineers and technicians, until the equipment is qualified and the equipment is put into production timely.

- Our engineers will provide customers with detailed inspection reports and company reference files so that they can understand the operation of the equipment at any time.

- We provide you with technical training, in addition, you can also have all kinds of professionals to the factory workshop to help you master the technology faster and more comprehensively;

- Provide one to three technical support services each year;

- Complete Spares inventory, in order to reduce the cost of spare parts inventory, provide better and faster service, we have prepared a set of equipment inventory, in order to meet the needs of the customers may need or period;

- I will arrange sending equipment regularly to the magazine for consultation and latest information. We provide one-stop service, from your warehouse design (water, electricity, steam), personnel training, equipment installation and debugging, lifelong after-sales service.

Contact Us

Send you inquery now!we will make a business proposal for you in 12hours!

-

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

High Capacity Carbonated Drink Production Line Machine For 500ml-2500ml Bottle

This machine is mainly used for filling carbonated drinks. I...

→ -

2000~18000 BPH Bottle Carbonated Drink Production Line Automatic Rotary

2000~18000 BPH Bottle Carbonated Drink Production Line Automatic Rotary

This machine has the advantages of high reliability, high ef...

→ -

Stainless Steel Carbonated Beverage Filling Machine , Fully Automatic Soda Filling Machine

Stainless Steel Carbonated Beverage Filling Machine , Fully Automatic Soda Filling Machine

This equipment is mainly used for filling all kinds of carbo...

→ -

Commercial Automatic Carbonated Drink Production Line Big Capacity For Coca – Cola

Commercial Automatic Carbonated Drink Production Line Big Capacity For Coca – Cola

Automatic Carbonated Soft Drinks (CSD) Drink Production Line...

→